Building beyond Earth: What’s in it for photonics?

When Sputnik launched on 4 October, 1957, it was the first human-made object to orbit Earth. The Russian satellite reached space atop a R-7 Intercontinental Ballistic Missile, prompted the establishment of NASA, and triggered the Space Race. Yet, despite the admiration — and fear — that Sputnik sparked around the world at the time, few could have fathomed the sheer numbers of spacecraft that followed.

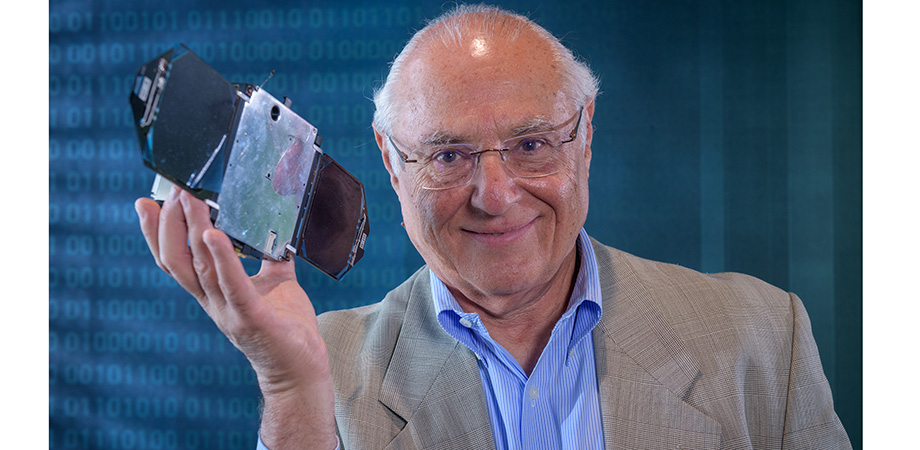

Thanks to the development of small satellites and modern rockets, the cost of making and launching spacecraft has plummeted, and satellites in space have proliferated. Today, around 12,000 satellites orbit Earth and come 2030, the US Government Accountability Office estimates numbers will soar to more than 60,000. Nanosatellite and 3D laser micromachining pioneer, Henry Helvajian, is a Principal Scientist at The Aerospace Corporation, a non-profit, and federally-funded research and development center committed exclusively to the US space enterprise. He reckons this figure could be closer to 100,000, once spacecraft launched by nations outside of the West are added to the count.

In his Plenary Hot Topic, “The changing landscape of outer space,” on Monday 27 January, he described what this means for space and photonics technologies. “Today we only service spacecraft when absolutely necessary but by the 2030s, in-space services, with refuelling, repair, relocation, assembly and manufacturing, hopefully will be routine — some finance groups forecast the market to be as large a multiple trillion dollars in 15 years,” he says.

Microgravity manufacturing

Myriad organizations already manufacture products in low earth orbit for use on Earth, pursuing the enhanced properties that microgravity can bring. Helvajian points to the ‘Factories in Space’ database, founded by physicist and satellite engineer, Erik Kulu, which lists some 185 firms, including photonics firms, working on products in space for use on Earth. Amongst these, Flawless Photonics, Luxembourg, is pioneering the manufacture of optical fibers while Apsidal, US, is developing novel photonics.

Meanwhile, a recent white paper — Semiconductor Manufacturing in Low-Earth Orbit for Terrestrial Use — from NASA and Stanford University scientists, and colleagues, stated: “Earth’s gravitational forces pose substantial barriers to quick, high-yield semiconductor production... Transitioning this industry into space is the only path forward if the US is to keep pace with the technological arms race unfolding across the globe.

A SpaceX Falcon Heavy rocket carrying NASA's Europa Clipper spacecraft launches from NASA's Kennedy Space Center in Florida on Monday, 14 October, 2024. SpaceX has been instrumental in slashing craft and launch costs, all necessary for future in-space manufacturing. Credit: SpaceX

As Helvajian asserts: “The fact is, in-space servicing, assembly and manufacturing is real and it’s happening now. Globally, we do not realize how much our lives are tied to information that comes from space; weather, banking (funds transfer timing), location, communications.”

“It was always expensive to launch spacecraft but this has changed, and is about to change even more,” he adds. “Look at SpaceX’s Starship — this will eventually carry hundreds of tons into space weekly.”

Crowded space

A more crowded space, and thriving in-space servicing, assembly, and manufacture (ISAM) sector, could have a profound impact on photonics. According to Helvajian, these extraterrestrial activities will demand space-based fuel delivery systems and could well include large infrastructures with kilometers-long scaffold, where organizations can set up payloads. “Companies are already lining up to manufacture structural materials such as carbon fiber composites as a work around to the limitations of the rocket payload volume — photonics and lasers will play a key role in assembly and verification.”

Helvajian points out how laser-based 3D printing will be fundamental to the additive manufacturing of high quality components in space — the European Space Agency 3D printed the first metal part in space in September 2024. He also points to photonics in optical tracking, diagnostics, and communications applications. “Operations in space are typically done while traveling around seven kilometers per second — quick assessments and decision making will be important,” he says. “Optical laser communications can transmit key data, at line-of-sight, between spacecraft — Space X’s Starlink satellites already use this and others will follow.”

But as the number of satellites has risen, so has the level of accompanying junk — or space debris — and likely will for some time yet. Figures from the European Space Agency reveal some 40,000 plus space debris objects — greater than 10 cm in size — are in orbit. Meanwhile more than one million 1cm to 10 cm sized fragments, and 130 million pieces ranging from 1mm to 1cm in size, are also circling Earth.

Artist’s concept of SpaceX’s Starship Human Landing System (HLS) on the Moon –at 165 feet, it is the same height as a fifteen-storey building. NASA is working with SpaceX to develop Starship HLS to carry astronauts from lunar orbit to the Moon and back. Credit: SpaceX

“Developing a sustainable space environment is already an issue and if not resolved it’s going to be the Wild Wild West out there because of debris crashes,” says Helvajian. “A 1mm piece of debris travelling at orbital velocity is equivalent to a baseball flying at around 80 miles an hour.”

Clearly space debris collisions pose clear risks to ISAM operations, but again, photonics can be applied to the problem. The Aerospace Corporation scientist points out how satellite imagery can capture collisions while lidar can characterize space debris and track its orbit. “We can also use this approach to provide a potential ‘safe haven’ for new satellites as they are launched and placed in orbit,” he says.

Space standards

Growing industry interest in ISAM, and the growing problem of space debris, hasn’t been lost on US government and related organizations, now racing to work out how best to manage activities. Back in 2017, the US Defense Advanced Research Projects Agency (DARPA) set up the Consortium for Execution of Rendezvous and Servicing Operations (CONFERS) to “empower a robust space economy” — CONFERS is now a global trade association for the satellite servicing industry with members including Northrup Grumman, Astroscale, and The Aerospace Corporation. “It’s producing standards and rules for good behavior in space,” highlights Helvajian.

NASA also recently launched a national coalition, the Consortium for Space Mobility and ISAM capabilities (COSMIC), in response to US government strategy to develop its domestic in-space servicing, assembly, and manufacturing capability — Helvajian and The AeroSpace Corp are involved. And like-minded endeavors exist across Europe, Canada, Japan, and other nations.

As collaborations gather momentum, Helvajian is very hopeful that come the 2030s, ISAM activities will be well underway. “Northrup Grumman has already been carrying out commercial space servicing and the US, and our allies, are putting a sustainable set of rules for good behavior,” he says. “The transition [to space] is here and there are huge opportunities for photonics.”

Rebecca Pool is a science and technology journalist based in the UK. This article originally appeared in the 2025 SPIE Photonics West Show Daily.

| Enjoy this article? Get similar news in your inbox |

|